What Are The Causes Of Rust On Self-Tapping Screws And How To Improve Them?

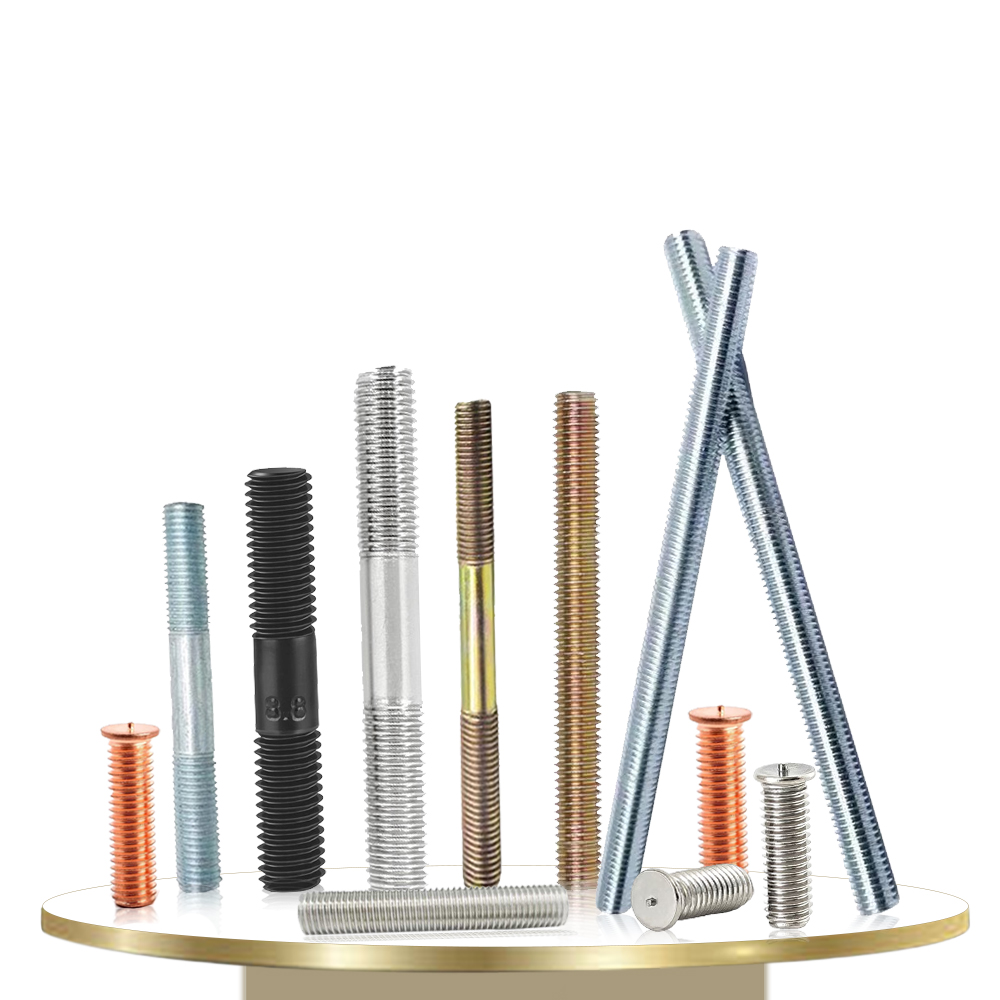

The so-called self-tapping screws are screws that can tap themselves, so they are suitable for fastening non-metallic or metal parts that do not require bottom holes and tapping. However, when such screws rust, it will affect the tightening effect, so we need to find the cause of the rust and provide ways to improve it.

Ordinary screws are generally flat-headed, and the head thickness is consistent, but self-tapping screws are pointed, so that they can complete the "self-tapping" function. They can rely on their own thread characteristics on the material being consolidated. The consolidated body is used to achieve the corresponding thread effect through the process of "tapping, drilling, squeezing and pressing", so that the consolidated body is tightly fixed together.

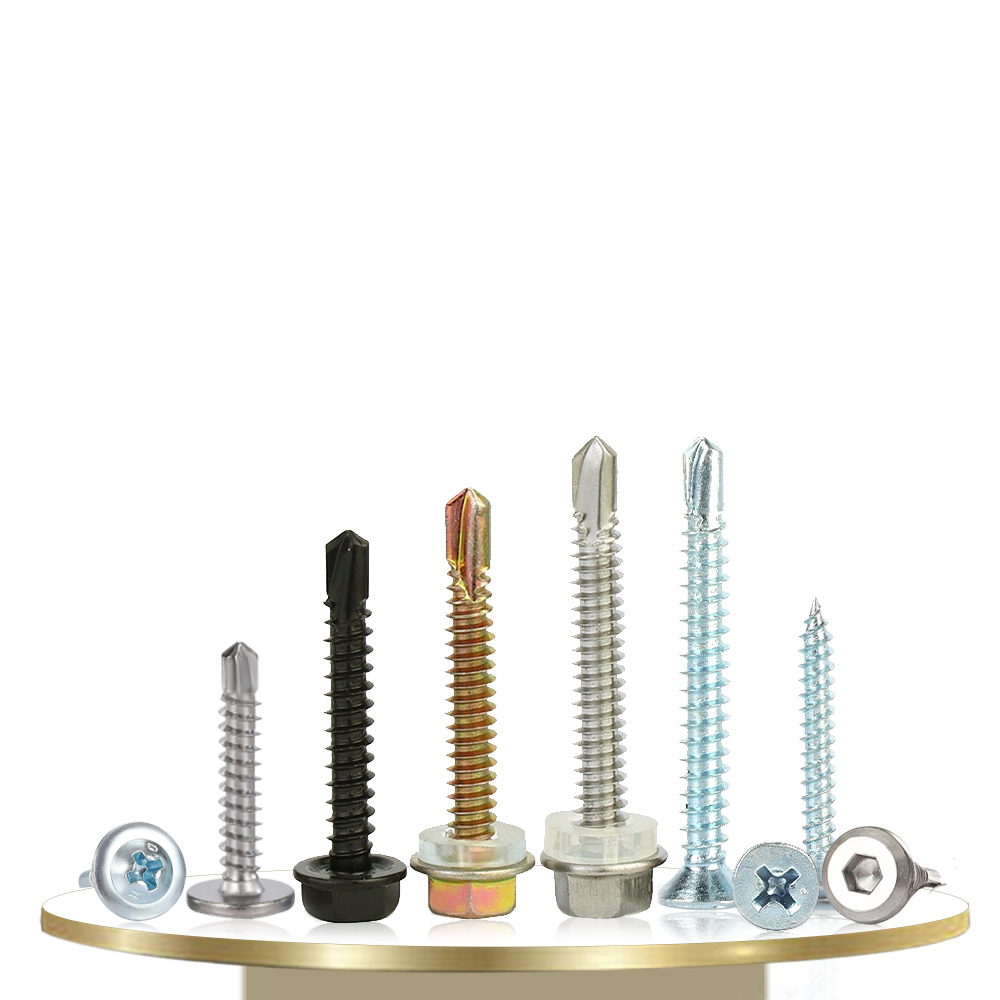

The reasons for screw rust are analyzed as follows:

1. Electroplating process issues. During electroplating, if the screws are not dried during the drying process, water vapor will remain. Or it has been dried, but condensation water formed during the packaging process, causing a chemical reaction between the water and the screws, and the screws rusted. In addition, if the plating is poor and the thickness of the plating layer is not up to standard, the corrosion resistance of the screws will be weakened and they will easily rust.

2. Storage or usage environment issues. During storage or use, unsatisfactory environmental conditions will cause screws to rust. For example, environments with high salinity, acidity, saltiness, high temperature, and high humidity will induce corrosion and oxidation of screws, leading to rust.

The improvement method is as follows:

1. Electroplating process. When electroplating, try to choose a plating color with a longer salt spray test time. Carry out electroplating strictly in accordance with the electroplating process and control the thickness of the electroplated layer. In order to improve the anti-rust ability, anti-rust paint can also be sprayed on the surface of the screws.

2. Storage environment. Place the packaged screws in a ventilated, dry environment away from direct sunlight. There should be a certain distance between the screws and the ground.

The reason why self-tapping screws rust is generally because the electroplating process is unqualified or the storage and use environment is not good. Therefore, if you want to prevent screws from rusting, you need to focus on these two aspects.

As China's leading self-tapping screw supplier, Aozhan Fasteners has been committed to providing customers with high-quality, reliable self-tapping screw products in a variety of specifications and models. We adopt advanced production technology and strict quality control to ensure that every self-tapping screw can meet customer needs and play its best role in various application fields. Aozhan Fasteners will continue to work hard to provide customers with better products and more professional services, and become a trustworthy partner of customers. If you want to know more, please contact us at info@aozhanfasteners.com. We are very happy to answer all your questions about fasteners.